Addressing Environmental Regulations With UVC LEDs

By Hari Venugopalan, director of global product management, Crystal IS

Global environmental concerns over water and air pollution are leading to new regulations that require real-time monitoring. Existing regulations are being tightened to monitor lower concentrations of compounds, and more compounds are being brought under regulatory control. As a result, companies and utilities will need to develop a network of cost-effective sensors for monitoring and response in real time. The use of optical spectroscopy with lattice matched UVC LEDs can address these requirements.

One of these regulations is the International Maritime Organization’s (IMO) standard for sulfur content in marine fuel to reduce sulfur dioxide (SOx) emissions from ships. In 2015, the limit for sulfur content dropped from 1 percent to 0.1 percent in Emission Control Areas (ECA), which includes North America and northwestern Europe. When the global limit drops to 0.5 percent in 2020, the shipping industry will face a difficult decision — switch to expensive low sulfur fuel (with an economic impact estimated at tens of billions of dollars annually) or implement new exhaust cleaning systems, which would be a less expensive alternative.

Monitoring Emissions — Sensitivity Depends On Light Source

Exhaust cleaning systems use gas scrubbers to reduce emissions. In addition to SOx, emissions from marine diesel engines contain particulate matter and PAHs or polycyclic aromatic hydrocarbons. Wet scrubbers clean a wide range of pollutants out of exhaust gas, including SOx and PAH. One of the principal challenges associated with wet scrubbing is handling the wash water discharge since PAHs are harmful to both people and the environment. Therefore, after scrubbing, the wash water is treated and monitored for PAHs prior to being discharged into the sea. This reduces the possibility of pollution shift from air to water, which would negate the environmental benefits of exhaust gas cleaning.

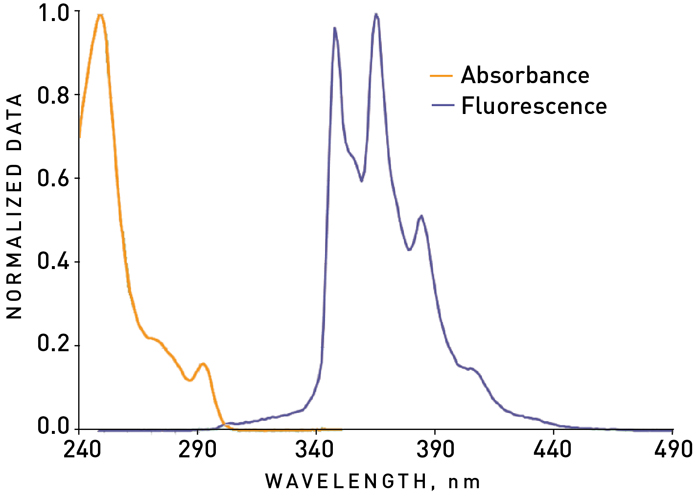

Low concentration levels of PAHs such as phenanthrene can be measured using fluorescence spectroscopy at 255 nm excitation. In fluorescence spectroscopy, the emission intensity (signal) is directly proportional to the concentration of the fluorescent compound over a wide range of concentrations. The emission intensity is also directly dependent on the intensity of excitation, so the higher the intensity of the light source at 255 nm, the more sensitive the detection.

Figure 1. Absorbance and flurorescence spectrum of phenathrene

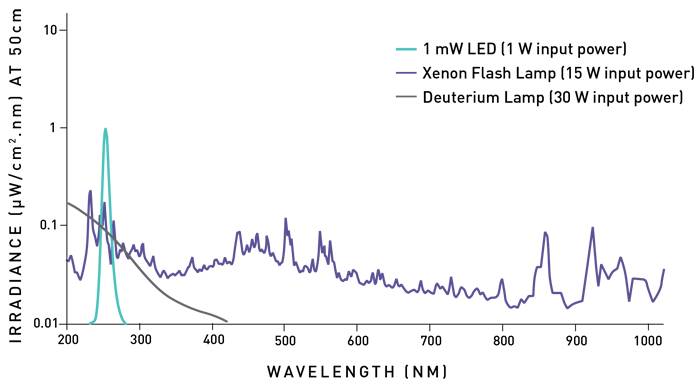

Fluorometers operating in the deep UV wavelengths have traditionally used xenon flash or deuterium lamps to access the UVC spectrum. While these UV lamps deliver sufficient light across the deep UV, they have relatively complex circuitry and require expensive filters to screen out unwanted wavelengths adding to total system cost. UVC LEDs offer a less costly solution because of their relatively inexpensive drivers and the monochromaticity of the light source eliminates the needs for costly filters. However, the adoption of UVC LEDs in fluorescence applications has been hampered by low light output and short lifetime of early commercial devices, which leads to poor sensitivity in the application. Newly available lattice matched UVC LEDs offer higher intensity at 255 nm than lamp alternatives (Figure 2), which leads to better sensitivity at lower PAH concentrations to meet IMO limits. Additionally, the longer lifetime of these UVC LEDs can extend light source replacement cycles, reducing cost of ownership.

Figure 2. Irradiance comparison of UVC LED, xenon flash lamp, and deuterium lamp at 255 nm

Increased Sensitivity — Benefits Of Greater Intensity

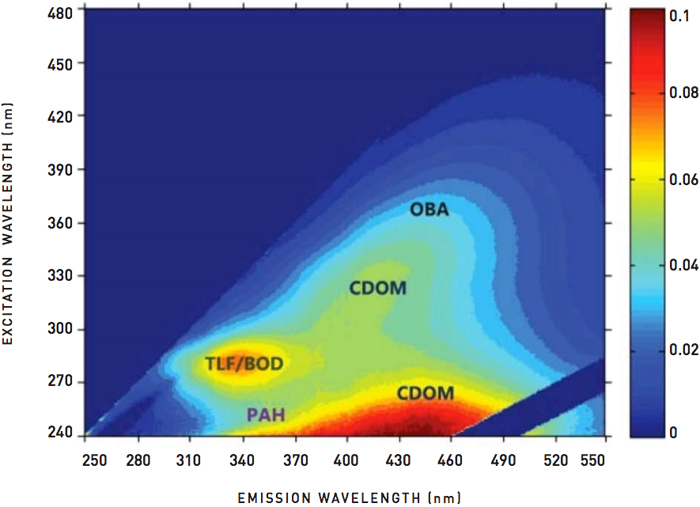

Newly available, highly sensitive fluorometers like the UviLux from Chelsea Technologies Group monitor PAHs, including phenanthrene, in exhaust gas wash water systems. The UviLux uses high-performance UVC LEDs as the fluorescence excitation source and a miniature photomultiplier as the detector with specific optical filtration providing the ‘tuning’ required to target various measurement parameters. In addition to PAHs, these fluorometers can be configured to measure parameters such as colored dissolved organic matter (CDOM), tryptophan-like fluorescence (TLF), biological oxygen demand (BOD), and optical brightening agents (OBA) (Figure 3).

Figure 3. Fluorescence excitation-emission matrix of a natural freshwater sample, indicating PAH, TLF/BOD, CDOM, and OBA, as measured by Chelsea Technology Group’s UviLux fluorescence sensor

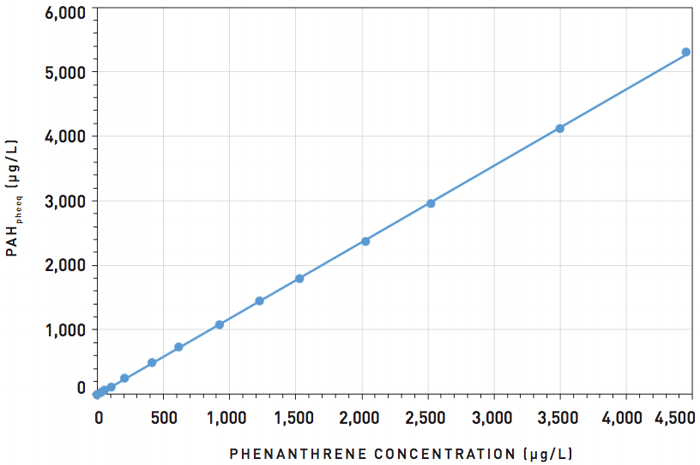

When used in systems for exhaust gas wash water monitoring, the sensor allows customers to meet IMO environmental regulations around monitoring wash water for PAHs (defined as phenanthrene fluorescence equivalence), pH, turbidity, and temperature. By incorporating a lattice matched deep UV LED at 255 nm to target phenanthrene fluorescence, Chelsea Technologies is able to offer industry-leading sensitivity. In addition, by combining absorbance and turbidity measurements, a correction is made for attenuation effects in the sample, which can be problematic in wash water with high color and/or turbidity. PAHs can be monitored over the required range of 0 to 4500 µg/L phenanthrene equivalence, in water turbidity up to 1000 formazin turbidity units (FNU).

Figure 4. UviLux PAH+ sensor dose-response curve to phenanthrene, demonstrating the excellent linearity (R2 = 0.99998) that can be achieved across the full range from 0 to 4500 µg/L, with integrated absorbance correction

In addition to the high sensitivity and linearity of measurement provided by the UVC LED, the long lifetime extends the calibration and maintenance period for the customer. This coupled with the excellent reliability of lattice matched UVC LEDs allows for a long-lifetime sensor that enables customers to comply with IMO regulations without the high cost of switching to low-sulfur fuels.

Regulatory trends across environmental sensing markets continue to increase, as does the availability and performance of UVC LEDs. Lattice matched UVC LEDs offer manufacturers design flexibility, high light output and stability, lifetime advantages, and environmental friendliness. By developing sensors with UVC LEDs instead of UV lamps, manufacturers can reduce costs and improve performance while meeting regulatory challenges.