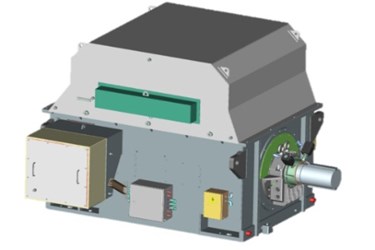

The Compact But Mighty N37 Induction Motor From GE Is Among The Highest In Power Density

- GE Power Conversion launches the N37, an induction motor with among the highest power density in its class

- An innovative upgrade to the well-established N3 motor line leads to a compact frame that doesn’t compromise on efficiency and reliability

- New standardized induction motor models fit a broad range of industrial applications

When it comes to technology, there seems to be no denying that smaller is better. The more advanced the world becomes in its capabilities, the more we rely on technologies to help us realize our maximum potential. More than ever, heavy industry is experiencing the same pressure to process more without compromising operational performance. Recently, GE Power Conversion announces its latest induction motor leading the way in facing the challenge.

With over one hundred years of experience in developing induction motor technology, the N37 induction motor is an upgrade to the well-established N3 motor line. It builds on a time-proven design with cutting-edge mechanics in order to meet heightened customer demands on footprint and performance.

Working to decrease the component weight, GE Power Conversion achieved an induction motor design with a dramatically increased power per kilogram ratio. At a lower frame size than conventional induction motors, this compact design translates to space savings and lower weight, essential both in onshore and offshore applications. The N37 squirrel-cage induction motors operate at 50 Hz and will soon be available in 60Hz.

The N37 is among the most efficient motors in its class. GE’s solution works to reduce energy waste while simultaneously reducing the operator’s environmental footprint.

"We’re constantly facing tougher demands in the power conversion industries – customers want products that are simplified, streamlined and compact but nevertheless meet increasing performance expectations,” said Luc de Camas, Product Leader, GE Power Conversion. “GE is responding to this call with the N37, which retains all the benefits of tried and tested technology but has been adapted to bring increased convenience to the operator.”

Furthermore, American Petroleum Institute (API) noise and vibration constraints were considered in the design of the N37. This reliable motor utilizes a rigid frame to meet all common industry requirements to help protect the wellbeing of onsite system operators.

The N37 launch marks the first of GE Power Conversion’s induction motors to be standardized for a wide range of industrial applications. It also marks a trend of meeting user demands for pre-engineered components and faster delivery times for Power, Water and Oil & Gas applications.

About GE

GE imagines things others don’t, builds things others can’t, and delivers outcomes that make the world work better. GE brings together the physical and digital worlds in ways no other company can. In its labs and factories and on the ground with customers, GE is inventing the next industrial era to move, power, build and cure the world. For more information, visit www.ge.com.

About GE Energy Management

GE Energy Management provides customers with electrical solutions that enable local utilities and energy-intensive industries to more efficiently manage electricity from the point of generation to consumption. GE’s Power Conversion business, a business unit of GE Energy Management, applies the science and systems of power conversion to help drive the electrification of the world’s energy infrastructure by designing and delivering advanced motor, drive and control technologies that evolve today’s industrial processes for a cleaner, more productive future. Serving specialized sectors such as energy, marine, oil and gas, renewables and industry, through customized solutions and advanced technologies, GE Power Conversion partners with customers to maximize efficiency. For more information, visit www.gepowerconversion.com

Source: GE