Britannia: optimizing the value of information

Contents

Capturing engineering information

Benefits of Directa

Early savings

Benefits beyond engineering departments

Bright future for Directa

What Directa can do

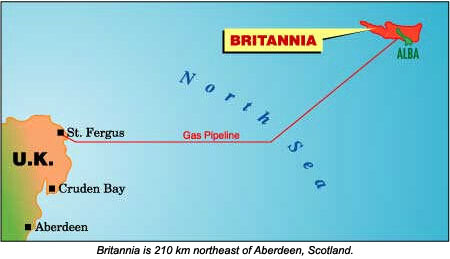

A joint venture owned equally by Conoco UK and Chevron UK, the Britannia production platform came on stream in August 1998 serving the United Kingdom's largest remaining North Sea gas condensate field. At its peak, Britannia will supply eight percent of the natural gas Britain consumes—more than 740 million cf/d. The field is approximately 150 miles northeast of Aberdeen, Scotland, in the central sector of the North Sea, has a projected life of 30 years, and will produce 50,000 b/d of gas condensate.

With 17 wells covering an area that would just fit inside the northern half of the radial motorway around greater London, the North Sea field is the UK's largest to be developed using the principles of Cost Reduction Initiative for the New Era (CRINE), a joint UK government and industry initiative. Because of the innovative methods employed to integrate suppliers and contractors in the project, Britannia's total development costs are 20% (£300 million or US$489 million) below original projections.

Capturing engineering information(Back to Top)

Far-sighted planning ensured that all engineering information required for safe and efficient operations throughout Britannia's operational lifetime would be captured electronically during the design and construction phases of the £1.25 billion ($2.2 billion) project. Britannia adopted Intergraph's Directa system for the management of documents and associated data. Directa is the part of Intergraph's modular information management solution, covering documents, tags, and assets. Since Britannia's primary focus is on document management, this solution was enhanced to ensure seamless integration with Britannia's tailored maintenance management system.

Before Britannia became operational, every group was asked for a priority list of documents to be included in Directa so that from the beginning there would be a nucleus of scanned and electronic documents in the system covering issues such as safety, production, and environmental performance.

Benefits of Directa(Back to Top)

Directa enables immediate electronic access to information that reflects the operational status of the plant from a single, verified source. It also avoids one of the failings for which big projects are notorious - uncontrolled, superseded documentation.

As Clive Randall, the project transitional coordinator, explained, "Once you have instilled the concept of a single source for documentation in the culture, you have a procedure that will put the latest version of a document into your management system."

This is crucial not just for safety, but also for day-to-day operations. With revenue from the field running at around £2 million ($3.3 million) a day, any interruption to Britannia production must be minimized.

"We have a maintenance system to look after issues such as inspection, replacement, and overhaul, with links from Directa to relevant documents," said Randall. "In the case of unscheduled maintenance, Directa will come into its own because we know that we can rely on getting the right version of documentation to deal with the problem. Speed of access to information is vital."

Britannia records manager, John Barrett-Spring, echoed this view. "We wanted a product that was quick, easy to use, guaranteed to work, and would deliver data to the people offshore when they needed it.

"If they were still relying on traditional methods and could not access the right information during a maintenance shutdown, it is conceivable that the cost in lost production time would soon equal the cost of an entire Directa system," Barrett-Spring said.

Early savings(Back to Top)

An early benefit of Directa was that there was no need to go through a time-consuming and expensive conventional handover of information between the development and operational phases, as well as at later stages of the life cycle. This is an important consideration because, on major projects like Britannia, a handover typically involves transfer and assimilation of truckloads of documents, an exercise that can easily cost several million pounds. By adopting Directa to store documents and data electronically, Britannia has created a single source of information, accessible to multiple users - whether they are onshore or offshore, contractors or suppliers.

Britannia's Directa system contains references to 45,000 documents. Additional capabilities, such as searching for information by tag number, have also been introduced. A user of the maintenance system can identify a tag and request all associated documentation managed by Directa. A list matching the search criteria is then returned to the maintenance system. In other words, users within the maintenance system environment can send requests for information to Directa and obtain answers without having to switch systems to gain access.

Documents can range in size from single-page technical drawings or purchase orders to volumes containing hundreds of pages. By making it quick and easy to find an online document—and by making that document more intelligent than a paper copy—the objective is that the system will enable Britannia staff to maintain electronic documents in Directa instead of paper documents.

Benefits beyond engineering departments(Back to Top)

Indeed, it is intended that Directa will eventually become an integral part of Britannia's lifetime operational and maintenance program. As part of this strategy, the main engineering contractor can access the system to create documents inside Directa and also manage changes. Subject to certain controls, Britannia is now planning to extend this capability to its accounting contractors.

To date, Directa has met with most success in technical documentation. "Britannia's technical document users are really very positive and very upbeat about Directa and its ability to handle engineering and maintenance information," said Randall.

"Some of the experienced team leaders offshore who have been on many different platforms say Directa is the best document management system they have ever worked with. They like its usability and the fact that the engineering information they want will actually be there when they want it," he said.

This was a vast improvement over projects in which access to information was unreliable and engineers would have to wait for it to be faxed or have a physical copy delivered.

Britannia archived all critical information in Directa, but around 10% of project information may never be captured digitally because some documents rarely need to be accessed, if ever. Instead, they are archived by the vendors. For example, certification data relating to a generator supplied to the fabricator will probably never be needed again. In such a case, the vendor archives the information, which is referenced on the Directa system with supplier contact information. Where a document is available online, eventually all paper copies will be destroyed except those required for statutory or legal reasons. For the moment, all data is being backed up by hard copy for a minimum of two years. If no problems arise, Britannia will then review its policy on retaining paper documents subject to operational and legal requirements.

Bright future for Directa(Back to Top)

Looking ahead, Britannia can take advantage of Directa's modular potential by moving toward a complete engineering information management solution. It is already developing links to tags to more closely integrate with its maintenance system, so that tags and assets can be used to access categories of information.

"A measure of Directa's success is that the operators wanted to use it since we first discussed its capabilities. In fact, we had them on board before wheeling it out to all our users," Barrett-Spring said. "Since they are happy, too, we obviously have a real success!"

"I like demonstrating Directa because I know how good it is," he concluded.

What Directa can do(Back to Top)

[This case study was provided by Intergraph]