Connecting The O&G Sector Through IoT: Key Features And Smart Methods

By Sanjeev Verma

Oil and gas is one of the largest and oldest sectors in the world, generating huge profits in terms of dollars. Factually, the O&G sector generates an estimated amount of $3.3 trillion annually. Oil is a crucial energy source that significantly relates to the global economic framework, especially for largest oil-producing countries: the United States, Saudi Arabia, Canada, China, and Russia.

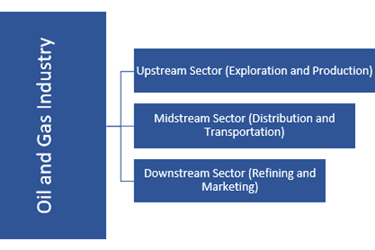

The petroleum industry is further divided into three main segments — upstream, midstream, and downstream, which characterize the oil and gas businesses via integrated companies present in all these three sectors.

Importance Of IoT In The Oil And Gas Sector

The Internet of Things is driving the transformation in the oil and gas sector. It includes exploration works, drilling, production, and transportation activities, often in the remote locations. In an O&G industry, there is a multitude of assets that need optimization and real-time tracking to work efficiently. IoT comes with great power to connect the plant managers with smart applications like real-time data processing, predictive and preventive maintenance, asset and inventory management, environment monitoring, and worker safety. Using different IoT techniques, the workers are now taking faster and accurate decisions.

Communicating in Real-time: Through IoT and its smart methods, it has now become easier to interact within and outside the refineries. Traditional ways of operability are replaced with internet connectivity, which is much faster as compared to the old telephonic communication. Now, if there are any changes or fixes, the message is sent automatically via the internet to avoid the delays. It has led to superfast operability without any delays and in real-time.

Reduced Carbon Footprint: Technology is continuously bringing changes in the way we live. It is thus significantly impacting the environment with smart concepts, allowing the industries to contribute their bit in reducing the carbon footprints. The oil and gas industry produces significant amounts of smoke and wastewater, making it one of the largest producers of greenhouse gas emissions in the U.S. The Internet of Things helps the industry achieve value-based outcomes that benefit the economy as well as the environment.

Human Safety: The employees of the oil and gas industry face a huge risk of working in a hazardous environment that can lead to accidents such as oil spills. Approximately 400,000+ people work in the extraction sector of the oil and gas industry, where these workers are exposed to huge risks of life loss. Also, the risk factor of a person working in an O&G sector is more than 7 times the person employed in other industries. Hence, IoT-powered sensors are installed on the assets to provide real-time notifications about the equipment related issues. If any equipment needs to be fixed or requires replacement even before the replacement date, IoT uses predictive maintenance to make it possible. IoT also helps in the production processes and ensures employee safety on the account of equipment maintenance.

Smart IoT Methods: Creating A Better Future For O&G Sector

Equipment Health-check and Preventive Maintenance

The Oil and Gas sector has been established long back and the biggest challenge arises with its legacy infrastructure. It becomes difficult to install sensors on the old types of machinery, which leaves with only 3 percent of the captured data for further analysis. However, IoT comes with the ability to capture multiple data points from multiple devices simultaneously. It then uses this data to determine the health of the equipment and allow the professionals to anticipate any issues. The correct usage of the IoT methods leads to more efficiency, less machine downtime, and enhanced productivity.

Remote Asset Tracking

There are a vast number of assets in the petroleum industry and most of them are established far away from the refineries. IoT is transforming the operations field with its ability to interconnect each asset. With the implementation of smart concepts, it is very easy for managers to perform operations remotely. IoT allows the benefit of real-time asset tracking, so O&G plant operators can easily track the live situation of the pipelines, oil wells, etc. It thus increases the efficiency of the assets along with predictable lifecycle management, no matter where they are located.

End-to-End Connected Pipeline

The O&G industry includes a huge gas pipeline system for distribution of the oil across the world, which needs to be connected through technology for proper management. IoT uses a central controlling system with sensor devices to collect data from each pipeline and use it for further analysis. The entire pipeline array consists of an end-to-end connection facility to monitor every aspect like pipeline temperature, flow, pressure, etc., providing real-time control. The connected pipeline system is one of the most effective IoT methods to implement in an O&G industry for enhanced productivity.

Offshore Rig Monitoring

In the O&G sector, most of the pipelines and equipment are below sea level, and it is quite difficult to inspect these assets. The advent of IoT has cleared all the ways of difficult situations with its smart solutions, helping the industrialists to manage and maintain the machinery at an advanced level. Offshore rig monitoring is a type of remote monitoring that helps track the live conditions of the subsea pipelines. It has transformed the traditional ways of visually monitoring a rig by introducing ultra-sensitive sensors that detect all the possibilities of rig cracks or malfunctioning and provides an immediate alert for analysis.

Level Monitoring

The oil business requires extra security, for there are easy chances of oil theft. Also, keeping a regular check on the oil levels is a must for proper management of the refinery. Hence, a level monitoring system comes into place, which allows the authorities to frequently check the oil levels and stay alert in case of any issues. This IoT-powered solution provides an accurate real-time check on the fuel stock level in the tanks remotely. Furthermore, it is a scalable solution that optimizes the inventory levels, saving a lot of time to provide exact fuel dispense.

Multiple Business Opportunities Through IoT

Currently, the driving factors of the oil and gas industry are mobility, data analytics, asset and inventory management, cloud storage, and lower infrastructure costs. Therefore, IoT adoption enables more informed decision-making and is focused mainly on efficiency. As the overall production costs are rising, the Internet of Things is bringing immense business opportunities to retain and hire workforces. Also, with the growing technologies and stabilized pricing, the O&G sector confidently accepts and adapts to the smart IoT methods. There are huge investment opportunities in the O&G market, and incoming IoT systems have revealed many folds.

Sanjeev Verma is the founder and CEO of Biz4Group, based out of Orlando, FL. He has conceptualized the idea of Biz4 Brand and founded Biz4Group and Biz4Intellia. He has 20+ years of experience in boosting IT-based startups to success. In the past, he has worked on leadership positions with Marriott Vacations, Disney, Mastercard, State Farm, and Oracle. Biz4Group excels in developing, implementing, and monitoring digital solutions ranging from IoT solutions and products, mobile and web development, and digital marketing to full stack development and CMS solutions.

Sanjeev Verma is the founder and CEO of Biz4Group, based out of Orlando, FL. He has conceptualized the idea of Biz4 Brand and founded Biz4Group and Biz4Intellia. He has 20+ years of experience in boosting IT-based startups to success. In the past, he has worked on leadership positions with Marriott Vacations, Disney, Mastercard, State Farm, and Oracle. Biz4Group excels in developing, implementing, and monitoring digital solutions ranging from IoT solutions and products, mobile and web development, and digital marketing to full stack development and CMS solutions.