Deepwater AUV now operating in US Gulf

The Hugin 3000, rated to 3000-meters water depth, is 5.3 meters long and is powered by a state of the art aluminum oxygen fuel cell battery, providing a mission endurance of up to 48 hours before resurfacing. The unit is integrated with a variety of survey sensors including the EM 2000 multibeam echo sounder for swath bathymetry and imagery. Other survey sensors include chirp side-scan sonar, a chirp sub-bottom profiler, and a cesium magnetometer. Underwater positioning will be performed using a HiPAP SSBL (Super Short Base Line) system integrated with Doppler speed log, an inertial navigation system, and for surface reference, dGPS. Acoustic links for control of the vehicle, reading of sensor data and emergency control, is also part of the delivery.

The Hugin 3000 is the new and third generation of the preceding Hugin prototype vehicles, which were developed and operated in partnership with Statoil, the Norwegian Defense Research Establishment (FFI), and Norwegian Underwater Intervention (NUI). The Hugin project started in 1995, and the Hugin vehicles have now performed more than 100 missions, including several commercial pipeline route surveys for Statoil in Norwegian waters. They have so far been proven very cost effective, and will enhance quality of survey data compared to existing methods.

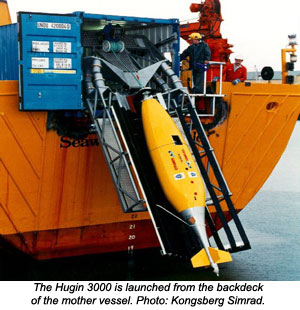

The Hugin is designed to meet deepwater survey challenges worldwide. In the US Gulf, it will be performing beyond the continental shelf to carry out Minerals Management Service (MMS) block surveys and pipeline hazard surveys. The AUV is launched from the mother ship and collects data on a pre-defined route stored in its computer's memory. The route can be altered during the survey as deemed necessary via an acoustic modem. Its multibeam echosounder, side-scanning sonar, and sub-bottom profiler are used to collect ocean floor depths and sub-bottom data. Salinity, temperature, and depth are processed on board by the Hugin's internal computer. The data collected with C&C's Hydromap proprietary software are analyzed in the AUV's computer and sub-samples are transferred with an underwater acoustic modem to the mother ship. This sample data are used to confirm the validity of the route and to assure quality control of the collected data.

A deep-towed side-scan sonar system has historically been the deepwater survey tool required. This system usually included a side-scan sonar accompanied by a sub-bottom profiler. Multibeam bathymetry was collected from a hull-mounted or over-the-side mounted transducer. The sonar was usually towed behind the vessel at a speed of two knots. It was necessary to tow the sonar at this speed and use a length of cable of at least three times the water depth to allow the sonar to be towed at a sufficient depth. Not only does the slow speed increase the cost of the survey, but the cable length means two to three hours are required to make a single line turn. Because the towed sonar was so far behind the tow vessel, a second vessel was usually necessary to position the towfish. Finally, the towed system often missed its target due to cross currents.

The benefits of an AUV, which is an untethered survey tool, are obvious as the speed is twice that of a towed system, line turns take about ten minutes, a second vessel is not required to position the system, and the AUV can fly the exact route even over rough terrain. With the oil and gas industry moving toward the deepwater reservoirs, the AUV future is quickly becoming a reality.

Edited by Dev George

Managing Editor, Oil and Gas Online