Facing Up to Shallow Gas Production

Contents

- Unexpected pressure problems

Historically, it has been the effort to drill and complete wells at ever-increasing depths that has driven technological innovation. But as oil companies seek to exploit relatively shallow reservoirs, they are finding a whole new set of technological and economical hurdles. This is especially true when the target is shallow gas deposits trapped in geographically young, Miocene formations. Such reserves are most often formed by gas that has migrated upward along a fault line until it eventually encountered a trapping and sealing mechanism at 2,000- to 3,000-ft below the surface. In rare instance the sealing trap is at even shallower depths.

Because they are so close to the surface, such reservoirs often come as a surprise to operators who discover them only accidentally while drilling to a much deeper target. Like a section of terrain mapmakers considered too inconsequential to plot, these zones are so shallow they are rarely sought or processed in a seismic survey.

Unexpected pressure problems (back to top)

As a result, a driller's first encounter with them is while drilling the upper section of the hole while the wellbore is filled with only fresh or slightly brine water. The unexpected gas pressure can present a well control problem as the pressure, though not high, is often enough to displace the water and flow to the surface. In most instances the event is treated as an easily controlled gas bubble. At its worse the surprise pressure forces an operator to set an unplanned for string of surface casing across the troublesome zone.

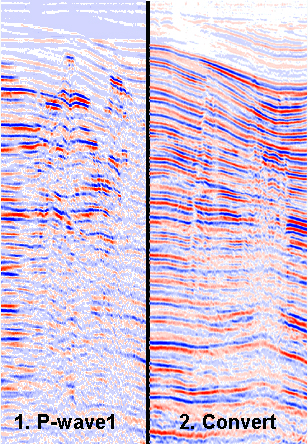

In this example from the Far East, gas had migrated through a fault and accumulated in the overburden. The compressional or P-wave image (left) is severely distorted making velocity analysis and structural interpretation inaccurate. The converted wave image (right) clearly shows the underlying structure, enabling more accurate velocity analysis and interpretation of the reservoir. [Images courtesy Schlumberger]

Also because shallow gas formations are unexpected and assumed to be quite small, they often go undocumented, even after being drilled, because oil companies seldom take the time to run logs across them. Therefore, unless the same reservoir is encountered at similar depths by the same operator (or by different operators in the same area sharing information), any commercial amounts of gas that do exist are likely to go unexploited even as the area's deeper formations are drained.

Once an operator does focus on these deposits, they often are troubled to find that though drilling and completing to them is relatively inexpensive, their gas volume-to-pressure relationship can still render them uneconomic. That is because shallow gas deposits do not have the weight of the earth pressing on them as do deeper deposits. The earth above them tends to be depositional and, at least geographically speaking, light. That lack of what is called geopressure means the gas is not compressed which presents a number of technological and possibly costly operational challenges.

During the drilling of these zones, though the gas can hardly be called high-pressure, it does exceed that of an empty wellbore and for safety reasons is generally assumed to possess a slightly greater pressure gradient than clear water. Therefore, in order to control the gas while drilling through the formation, drilling fluids must be weighted with solids. At the same time, great care must be taken to minimize the amount of these solids that are allowed to enter, or invade, the highly permeable formation and form what drilling and completion engineers refer to as a skin.

As the name suggests, a skin left by drilling fluids forms a thin barrier between the formation and the wellbore. After drilling and perforating the formation, acid is often pumped into the zone of interest to remove skin and damage that may have been caused by perforation debris.

In deeper, more conventional reservoirs, it is normally enough to reduce skin thickness for the pressured gas to flow. In uncompressed gas formations, however, the skin must be almost totally eliminated. It is a nearly impossible task, accomplished only when operators minimize skin occurrence by paying meticulous attention to the quality both of the materials used in an acid job and the actual performance of both the acidizing and original drilling operation. On a drilling location, particularly offshore, such vigilance is a time-and money-consuming task.

The geologic youth of shallow reservoirs, particularly offshore, means they are formed of unconsolidated sands that can shift and actually flow as gas is produced. To combat this problem, the reservoirs are treated, as are most offshore gas formations, with gravel packs. Gravel packs are a system of sand packed into screens that have been run with the production tubing. When sand is flowed into these screens they form filters to prevent formation sand moving into the wellbore with the produced gas, eventually plugging flow.

Lack of gas compression (back to top)

The lack of gas compression in these zones also means gravel packs, once in place, must themselves not become a source of flow resistance. Such a situation can easily arise as a result of the chemical compounds, known as gels, which provide the viscosity necessary to carry the sand in solution from surface to formation. Once the sand has been deposited in the screens, the gels must break up, either as a function of temperature or time, and dissolve into a water-like compound that can be washed from between the sand particles they once buoyed.

Also as a consequence of low gas compression, these formations must cover considerable acreage in order to contain enough gas in place to justify development economically. And while these young formations tend to possess good continuity and, therefore, the ability to flow across the reservoir, the reserves must be produced quickly to attain the rate of return so important to operators' bottom lines.

Though intuitively one would expect the opposite to be the case, these low-pressure gas zones often require heavier-walled tubulars than do normally pressured ones. This is because they must be forced to produce at rates sufficient to pay for themselves. And since these gases are not compressed, the only way to increase the amount of gas flowed per unit of time is to increase flow velocity. In many instances, that velocity must approach what is often termed erosive velocity, around 55 ft per second, and as the name implies a velocity at which the gas will cut through standard tubing.

Of course, to reach these velocities, almost from the first, these wells must be assisted by compressors. On land this is not often a significant problem as in the larger scheme of things compressors are not particularly costly.

But offshore, though the cost of compressors represents even less a percentage of project overall costs, the space that must be allotted to support them can have considerable impact on capital expenditures. That is because in most offshore production budgets, the greatest initial outlay is for the platform. The cost difference between a basic platform on which a few christmas trees are housed and one with sufficient surface area to place a compressor is substantial. In some instances, it is a difference sufficient to scuttle an otherwise economic project.

The problems associated with producing shallow, low-pressure, high-volume, gas are many. But given sufficient reservoir acreage and available surface space many smaller companies are cashing in on these formations on which larger companies are loath to spend money and talent or have missed entirely in pursuit of other prizes in the area. And as gas prices rise and technologies such as shallow seismic and multilaterals become more common and less expensive, the opportunities for companies in these shallow gas plays will only improve.