How Is IoT Technology Enhancing The Fuel Level Monitoring System?

By Sanjeev Verma

The low maintenance of the fuel record and gas consumption in vehicles has led to a better management system wholly based on Internet of Things (IoT) technology. The IoT concept is quite prevalent in the fuel industry, with its automation techniques and rendering simplified solutions for management. Moreover, it offers judicious use of fuel, thereby eliminating the possibility of fuel wastage. As fuel costs rise, consumers are looking for more advanced and economic solutions that help in real-time fuel monitoring. This plays a crucial role in providing the managers with accurate fuel information so that they can easily detect the availability of the stocks.

The Significance Of IoT In Monitoring Fuel Levels

The use of IoT in the gas industry is offering huge benefits to manufacturers and industrialists by initializing sensor-based technology. It cumulates the working of gateways and interconnected assets within the industrial premises that enable effective productivity. IoT technology works on a data-driven approach, improving service quality through analytics and providing accurate insights. This enables the managers to make effective business decisions and conclude better progress.

IoT technology plays a crucial role in allowing users to monitor the tank levels remotely and identify abnormalities like leakages, machine idling, fuel consumption, etc. Identifying the potential improvement areas enables accurate results and actionable insights, which greatly impacts direct business growth. Apart from industries utilizing fuels for processing, IoT also incentivizes fleets with its automation techniques and sensor-based modules. The sensors get installed on assets like tires, fuel tanks, wheel axles, and others, fetching the data to perform advanced analytics. This creates a whole model/solution where the drivers and fleeting managers can instantaneously know the entire vehicle condition, especially the fuel consumption patterns.

Additionally, the solution is highly compatible with all kinds of tanks — symmetrical or asymmetrical — making it a bonus add-on for the fuel business. Using IoT-powered solutions for fuel monitoring provides better business opportunities and growth in terms of efficiency and industrial functioning.

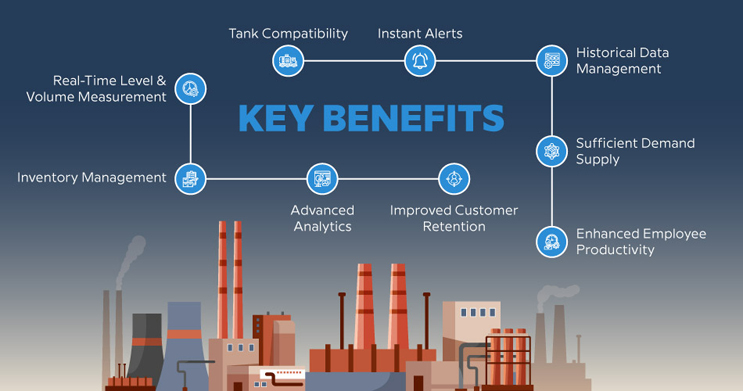

Key Benefits Of Installing An IoT-Powered Fuel Level Monitoring System

- Real-time level and volume measurement

- Inventory management

- Tank compatibility

- Instant alerts

- Advanced analytics

- Historical data management

- Sufficient demand supply

- Enhanced employee productivity

- Improved customer retention

An IoT fuel level monitoring solution enables ubiquitous monitoring of multiple tanks across different sites. It consists of a centralized dashboard that reflects relevant details of tank assets like location, real-time fuel level, volume, etc. The solution includes instant alerting, which triggers notifications on the smartphones of owners. It provides accurate measurement of the fuel levels through integrating advanced and latest sensor devices. The devices are weatherproof and render accuracy even while measuring the heating oil levels, without hampering the device performance.

The advanced analytics feature offers insights to actuate the real potential of the plant and enhances its workability through detailed report generation. It measures the level and volume of the fuel tank by assigning the latest sensor devices to the industrial assets and extracting the relevant information out of them.

A smart fuel level monitoring system enhances the inventory management process by providing advanced solutions. It addresses maximum issues for managers by extracting key information about assets and equipment health. IoT provides automated scheduling and monitoring of assets via interconnected sensors. These devices enable high efficiency of resource usages like fuel consumption patterns that contribute to effective productivity and eco-friendliness.

Industries having huge oil tankers and farms require a budgeted and effective solution to keep up with their inventories. The sensor-based system proves highly beneficial in such areas due to its instant alarming system that triggers the interconnected devices to take necessary actions in case of spills or leakage. This eliminates the necessity of putting in manual labor and automates the entire premises, covering the smallest of the details.

The solution also provides efficient data gathering at regular intervals, which allows managers to improve industrial performance. Furthermore, it adds to the industrial benefits by tracking the processes in real-time and rendering precise information. The smart fuel level monitoring solution comprises advanced software and hardware equipment, making it a fully-fledged system that works in any environment.

The use of IoT technology in today’s world is being rapidly promoted and accepted in various industries. It enables industrialists to have more simplified and smooth business management by covering the entire premises under automation. Since IoT utilizes sensor-based systems and gateway connectivity, it is lifting the business progress in every possible way. The industries are flourishing by getting their assets connected and utilizing data-driven insights to manage crucial tasks.

Sanjeev Verma is the founder and CEO of Biz4Group, based out of Orlando, FL. He has conceptualized the idea of Biz4Brand and founded Biz4Group and Biz4Intellia. He has 20+ years of experience in boosting IT-based startups to success. In the past, he has worked on leadership positions with Marriott Vacations, Disney, Mastercard, State Farm, and Oracle. The company headed by him excels in developing, implementing, and monitoring digital solutions ranging from IoT solutions and products, mobile and web development, and digital marketing to full stack development and CMS solutions.

Sanjeev Verma is the founder and CEO of Biz4Group, based out of Orlando, FL. He has conceptualized the idea of Biz4Brand and founded Biz4Group and Biz4Intellia. He has 20+ years of experience in boosting IT-based startups to success. In the past, he has worked on leadership positions with Marriott Vacations, Disney, Mastercard, State Farm, and Oracle. The company headed by him excels in developing, implementing, and monitoring digital solutions ranging from IoT solutions and products, mobile and web development, and digital marketing to full stack development and CMS solutions.