New deepwater fabrication facility being built on Texas coast

Increased drilling activity both on the Gulf of Mexico shelf and in deepwater worldwide has encouraged KOS to build the new facility and pursue the anticipated demand for offshore fabrication, says KOS President, Myron Rodrigue.

"We expect to successfully compete in the offshore fabrication arena, especially on large, complex deepwater projects. Our greatest assets are our people, our cohesive team and our commitment to safety, quality and productivity," said Rodrigue.

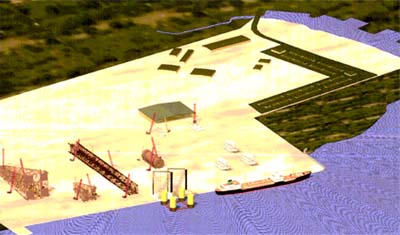

Artist's conception of the completed Kiewit Offshore facility.

He adds that a team of seasoned Kiewit employees, who have worked together in the offshore industry, will manage the new KOS facility.

Kiewit has been building oil and gas facilities for more than 30 years, from the Arctic Circle to West Africa. Previous companies managed and operated by Kiewit include Gulf Marine Fabricators and Bullwinkle Constructors. In addition, most of Kiewit Offshore Services' managers served in similar positions at Aker Gulf Marine. Kiewit has participated in some of the industry's most significant projects, including Bullwinkle, the world's tallest fixed offshore platform; Hibernia, the world's largest gravity-based structure; and major installations at Prudhoe Bay for the Trans-Alaska Pipeline.

High productivity

The new KOS facility has been designed from the ground up to deliver quality fabrication services. Using advanced automation, streamlined layouts and covered assembly buildings, the yard is designed for high productivity, which represents potential schedule reductions to projects, says Rodrigue.

"KOS is prepared to accommodate a wide range of offshore structures, from conventional fixed platforms to large, complex deepwater floating solutions," he added.

The 400-acre property—one of the largest in the Gulf of Mexico —will include 3,600 ft of bulkhead, built for heavy-loading conditions. With 45-ft water depth along the bulkhead, the KOS yard will be capable of handling complex integration activities for tension leg platforms (TLP) and floating production/ storage and offloading (FPSO) units.

The KOS yard also offers customers more than a quarter million square ft of covered work space, including four contiguous bays, climate-controlled storage building, and automated shape-cutting and brace-cutting facilities.

Major equipment, which will be on-site this summer, ready for work, includes 660-ton crawlers; material-handling equipment; and modular trailers, specially designed for moving large components.

Source: Kiewit Offshore