Stress Engineering Services Wins Top Commendation By U.S. Air Force After Delivering Revolutionary New Technical Package

Stress Engineering Services, Inc. (SES), the global leader in consulting engineering services and solutions, in collaboration with engineering software company, nTopology and the open additive manufacturing firm Origin, has been awarded first prize by the U.S. Air Force (USAF) for its work in designing, analyzing, testing and manufacturing a multi-material hydraulic tube clamp for an F-16 aircraft.

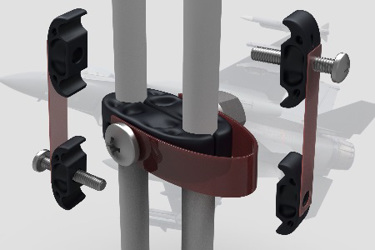

The USAF Rapid Sustainment Office’s (RSO) Advanced Manufacturing Olympics was held October 20-23, 2020 and the Approval Sprints Technical Challenge was one of five challenges that aimed to push the boundaries of additive manufacturing and reverse engineering. The first-place prize was awarded to the SES/nTopology/Origin team after they rapidly iterated on a design for additive manufacturing (DfAM) for a replacement candidate for the failure-prone C3175-9J clamp employed on the F-16 aircraft. The team exhibited highly skilled management of complex dimensional accuracy, stresses/loads, flammability compliance, low and high temperature ratings, fuel and fluid exposure and vibration tolerance to devise a polymer additively manufactured replacement solution.

In just three weeks, the team performed more than 100 tests on 400 parts, developing more than 30 separate designs, conducted advanced analysis, full-scale testing and final part production, through 100% virtual collaboration. The tube clamp submitted by the team exhibited twice the load bearing capacity as the original design, designed on nTopology software, using Loctite 3955, a flame-retardant chemically resistant material from Henkel, and manufactured on the Origin One 3D printer, and validated by SES using its advanced rapid digital qualification process.

Dr. Kenneth Bhalla, chief technology officer, SES, commented, “We are proud of the innovative methods and technologies our team showcased in exploring beyond the frontiers of additive manufacturing and earning a strong USAF endorsement of our technical capabilities. We were able to deliver a final printed F-16 hydraulic line clamp, a technical data package and an accelerated qualification strategy for full approval of proposed materials, machines and a complete family of components, while collaborating and innovating digitally across multiple offices and practices.”

Matthew Sanders, SES AMO team lead, said, “Rigorous verification and validation methods will always be required when new and advanced additive manufacturing processes, materials, and designs enter an industry. We are honored that the USAF recognized this technical package as being a revolutionary contribution to the advanced manufacturing sector.”

About Stress Engineering Services, Inc.

Since 1972, Stress Engineering Services, Inc. has been a global leader in consulting engineering services and solutions for a variety of industries. Stress Engineering Services is committed to providing the most comprehensive design, analysis and testing services with an unsurpassed level of engineering integrity and skill. The company’s multi-disciplinary engineering methods, advanced technology, innovative applications and highly knowledgeable and experienced staff provide proven, quantifiable benefits to its worldwide portfolio of clients. Stress Engineering Services is headquartered in Houston, with offices in Cincinnati; New Orleans; Baton Rouge, Louisiana; Calgary, Alberta; and Singapore. For more information, visit www.stress.com.

About nTopology

nTopology, headquartered in New York City, NY, is an engineering software company building the next generation of engineering design tools for advanced manufacturing. Their nTop Platform technology enables high-performance designs, lightning-fast iterations, and geometric complexity that were previously impossible to achieve. From its unbreakable modeling technology and field-driven design to remixable workflows guaranteeing repeatable outputs, nTop Platform empowers engineers and designers to create optimized parts meeting functional and performance requirements.

About Origin

Based in San Francisco, CA, Origin is pioneering the concept of Open Additive Manufacturing, a new way to build based on open materials, extensible software, and modular hardware. Origin One, the company’s manufacturing-grade 3D printer, uses programmable photopolymerization to precisely control light, heat, and force among other variables to produce parts with exceptional accuracy and consistency. The company works with a network of material partners to develop a wide range of commercial-grade materials for its system, resulting in some of the toughest and most resilient materials in additive manufacturing. For more information, visit www.origin.io.

Source: Stress Engineering Services, Inc.