Transiting rubble zone key to subsalt cementing

By John Murphy, Houston

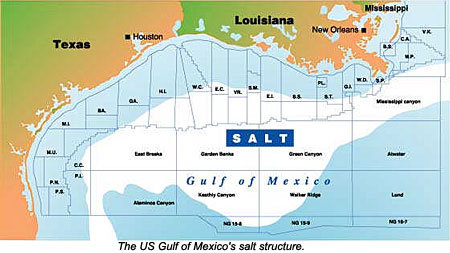

One of the vaunted advantages of recent advances in 3D seismic processing has been to allow operators "see" beneath salt formations. In days past, operators suspected, but could only guess at, the existence of hydrocarbon deposits beneath these massive sheaths. That, plus the fact drilling and completing in them is so difficult, has caused operators to avoid dealing with long sections of salt whenever possible.

Today, convinced salt formations in the US Gulf of Mexico and elsewhere cover huge oil and gas deposits, operators are actively exploring these once daunting plays. For service companies and drilling contractors, that has meant a sharp learning curve as they seek ways to set and cement casing across the salt formation and into the transition zone, known as the rubble zone, beneath it.

"The challenge of successfully cementing a subsalt well lies in achieving zonal isolation through the salt zone and in the rubble zone directly below the salt," said BJ Services' Cementing R&D section leader Dan Mueller. "A typical subsalt casing program calls for setting a heavyweight 9 7/8–in. casing through the salt and into the transition zone."

Much of the difficulty in drilling and cementing through salt lies in the fact the entire formation has a tendency to move, a phenomenon that can create numerous problems above, beneath, and within the formation.

"Above the salt, weak formations can result in loss returns while drilling or cementing," said Halliburton's Ronnie Faul. "Below the salt, weak and overpressured formations can cause lost returns and possibly cross-flows."

Of the two, it is the area beneath the formation known as the "rubble zone" that causes operators and contractors the most concern. Essentially a transition zone between the salt and more stable formations below, created as the moving salt churns the earth beneath its weight, engineers are never quite sure what to expect when the drill bit punches out of the salt and into this rubble zone.

"So much depends on the geology," said Triton Engineering Services' drilling manager Mike Truitt while discussing strategies for cementing through salt formations. "How the salt was formed, how it moved into place, and how it has moved since it came into place. And so much has to do with the geology beneath the salt."

Having developed methods for creating gage wellbores through most salts using saturated salt, synthetic oil- and oil-based muds, today's drilling engineers generally regard the transition zone as the real challenge to successfully completing a well in subsalts.

"This transition zone is normally rubblized and may contain a gas cap," Mueller said. "The trick is to be able to design the cement for such hazards as gas, lost circulation, gumbo, and others that may be present while achieving a bond in the salt section above."

Mueller reports his company has come to favor pumping a salt-saturated cement across the salt and tailing in with a cement designed for gas control. Others opt to pump 3% KCl across the salt and into the transition zone below.

"The salt formations have been typically drilled with a salt-saturated mud to avoid salt dissolution and formation washout and today many wells are drilled with oil-based or synthetic oil-based muds," said Faul. But, he says there can be complications from these systems of which cementers must be aware. "Contamination of the cement slurries with salt muds can cause adverse reactions, and the synthetic muds can leave a film on the wellbore and pipe that is impossible to bond to. This is typically solved with careful testing of the spacers and by incorporating salt compatible spacers for salt muds and special surfactants for the oil-based and synthetic oil-based muds."

The movement of salt formations is referred to as creep—a plastic flow behavior that can exert pressure sufficient to sheer or collapse casing even after it has been cemented into place. Creep, says Faul, makes it imperative cementing contractors use best cementing practices and sometimes multiple casing strings where casing is cemented inside casing to add collapse strength.

"Knowing it is a creeping salt is key," Truitt said. "You can only really know from experience in the area, and, if you don't know, you have to plan your well as though creep is present and as if no cement was in place. You cannot plan on cement for collapse strength but a good cement job becomes even more critical when creep is occurring because a good cement job helps support the pipe."

When planning for creep, engineers consider the overburden pressure of the salt as opposed to the pore pressure when picking mud weights and pipe sizes. This means that in a pore pressure environment that would normally require a 15 ppg mud say, a 19 ppg mud may be needed just to keep the salt movement from collapsing the borehole. Naturally that means the cement must be even heavier to displace the mud during cementing operations. And the casing used must be heavier than would normally be called for, both of which adds costs.

"You have to use a thicker wall pipe to maintain a sufficiently large ID through it. To drill out of it with a bit size large enough to gain the next hole size required by the well plan, you have to use a larger size pipe," Truitt explained. "So if you want to drill an 8 ½-in hole, you have to go from a 9 5/8-in casing to a 9 7/8-in so you have thicker wall to begin with. They are fairly common sizes, but some larger companies that know they are going to drill five, six, or ten subsalt wells or more will have casing specially rolled into what is called ‘gun barrel' pipe."

The nature of salt itself can cause problems within the formation. For instance, salt is a better conductor of heat than its surrounding formations. This means that temperatures at the top of the salt are typically higher than usual and lower than usual near the bottom. This can cause the cement to take longer to set up in some parts of the well than others, a problem best handled, said Faul, by adding KCl to the slurry in place of more commonly used synthetic retarders.

And in some rare cases, notably in Mexico's section of the Gulf of Mexico, other minerals embedded in the salt have caused cementing companies considerable headaches. One contractor working there reported mineral deposits in the salt caused both retardation and acceleration of cement hardening times.

Difficulties can also arise when the salt is fractured, particularly since 3D has made it possible to see in , around, and beneath salt formations, the pictures are still, as one engineer put it, "murky at best". "Odd problems can arise from faulting through the salt itself that can cause instability, particularly when it extends to the rubble zone," Truitt said. "And the rubble zone can be very unstable and present serious drilling and casing problems."

Since scientists can gain only a rough image beneath the salt, they often are able to only estimate the extent of the rubble zone, another source of consternation to engineers who over time have developed a rule of thumb correlating problems to transition zone length.

"Of course you don't know how long the rubble zone is or how rubblized it is," Truitt said. "If the transition zone is less than about 500 ft, it is generally more easily managed. Between there and about 1000 ft, it is more difficult, and when it is more than 1000 ft, it usually presents serious drilling problems."

The good news, reports Truitt, is that once through the transition zones, pore pressures and fracture gradients tend to stabilize, which means long sections can be drilled before a string of casing needs to be added. In instances where an extra string of pipe was required to get through the salt section or the transition zone, a saved casing string can make the difference between a production hole too small to produce large volumes of hydrocarbons and one sufficiently large to accommodate commercial rates.

Since the mid-1990s, when companies like Anadarko began pioneering the subsalt play with their Gulf of Mexico Mahogany project, drillers, cementers, and operators have learned a great deal about how to construct wells in and through large salt formations. According to Truitt, the key is to keep it simple while staying alert to possible problems.

"It's not rocket science, but there is a lot to consider," he said. "People have found out a lot of the things we know about now were discovered by accident, and we found that some things worked and others had dire consequences. We (Triton) are using a lot of what we have learned and what the industry has learned. The key is to keep it simple, assure a good wellbore, and use good cementing practices."