Using IoT-Based Tank Level Monitoring For Volume Measurement

By Sanjeev Verma

Level monitoring systems has successfully triumphed every implementation. Their deployments allow the users to measure the level of liquid stored in a container of any shape, size, orientation, or material. Powered with the advanced telemetric technology of Internet of Things, these systems measure liquid level without making any contact with the liquid and transmit the readings to a comprehensive platform suite.

While these systems offer major advantages to industries once they are installed, there are several drawbacks of liquid level measurement. First, measuring the level or depth of liquid in a tank doesn’t solve any industrial-scale requirement. While it helps in preventing the tanks to overfill or dry out, it doesn’t give clear visibility into the actual amount of liquid present in the container. In addition, saying that there is 200 liters of liquid present in the tank makes more sense than saying that there is 3.2 meters of liquid present in the tank.

Hence, volume is a much clearer and appropriate parameter used to track and monitor the contents of a tank. It not only gives a clearer picture about the availability of a particular liquid but also helps in evaluating its consumption and utilization in different areas of an industry.

But with what apparatus can someone roll out an industrial scale volume measurement solution. Do one need to procure a special system to do so or is there a more cost-effective alternative to this? Well, the level monitoring solution once deployed can be translated to calculate the volume of liquid present in the tanks. Let us see how.

How Will The Volume Be Measured?

The equipment and working of volume measurement is similar to that of the level monitoring. A sensor either drilled into the tank's lid, suspended in air over an open tank, or attached in the exterior bottom of the tank is used to measure the liquid level.

Once the readings are taken, they are gathered by a nearby gateway which then transmits it to a cloud-powered platform suite. These level readings are then used to calculate the amount of liquid stored in the tanks, doesn’t matter if they are symmetrical or asymmetrical.

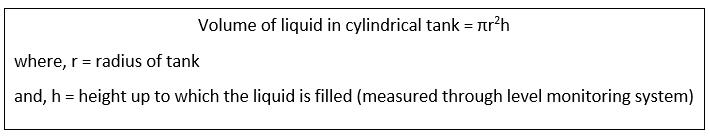

With in-built formulas and algorithms, the platform calculates the volume of liquid stored in regular containers based on its current level reading. For example, in an upright cylindrical tank the volume can be determined via the height up to which the liquid is filled, provided the radius of the tank is known. The following formula is used to determine the volume in this case:

Similarly, the volume of liquid in cuboidal, spherical, conical, or tanks with a combination of such geometries can be determined through the help of level monitoring. Also, the orientation of these tanks won’t pose a problem as long as the math can be worked out. Hence, even if the cylindrical tank was installed on its curved surface, the volume of the liquid in it could have been effectively determined.

But what about asymmetrical or custom shaped tanks. For specific industrial applications, there may be a possibility that symmetrical tanks may not be installed. An in-house manufactured tank may have to be built in order to facilitate storage and handling of liquid. How can the volume of such tanks be calculated?

For such tanks, the volume for every corresponding level reading must be known in advance. These analogous level and volume readings can be tabulated and ingested into the platform to help determine the volume with real-time liquid level readings. As soon as the gateway share the liquid level reading from sensors to the comprehensive platform suite, the platform can cross-check the reading in the pre-entered tabular data to determine the amount of liquid stored in the tank.

Hence, the amount of liquid content present in asymmetrical containers can be measured and remotely supervised at all times. This remote volume monitoring enables industries to track their inventory level, which then helps them to optimize their on-floor activities and reduce downtime.

How Volume Measurement Help Companies?

As discussed above, volume is a much better alternative than level to track the availability of a particular liquid. However, by measuring volume the consumption and distribution of liquid in a particular facility can also be tracked. Let us take an example to understand it easily.

Let’s say that there is a beverage industry that produces refreshing mango drinks. They have a cylindrical tank of 1,000 liters in which the concentrate for the drink is stored. With the help of volume measurement system, they came to know that they have 726 liters of juice concentrate available in stock. Hence, they can decide how much juice they can manufacture and can also determine the number of juice boxes they’ll be able to fill from the produced juice. Furthermore, they’ll also come to know if they’ll be able to fulfill the demand condition of the market and can accordingly procure more juice concentrate from their vendor if they need to.

Hence, this helps companies to optimize their warehousing capabilities, forecast and predict future needs, execute proper procurement and provisioning operations, and balance supply-demand conditions in the market.

Conclusion

The volume monitoring solution offers many benefits over simple level monitoring. And the best part about using IoT is that both these parameters associated with the tank’s content can be remotely monitored on a single platform in real-time. This comprehensiveness of the solution makes it a good fit for installation in multiple industries dealing with different kinds of liquids.

Sanjeev Verma is the founder and CEO of Biz4Group, based out of Orlando, FL. He has conceptualized the idea of Biz4Brand and founded Biz4Group and Biz4Intellia. He has 20+ years of experience in boosting IT-based startups to success. In the past, he has worked on leadership positions with Marriott Vacations, Disney, MasterCard, State Farm, and Oracle. The company headed by him excels in developing, implementing, and monitoring digital solutions ranging from IoT solutions and products, mobile and web development, and digital marketing to full stack development and CMS solutions.

Sanjeev Verma is the founder and CEO of Biz4Group, based out of Orlando, FL. He has conceptualized the idea of Biz4Brand and founded Biz4Group and Biz4Intellia. He has 20+ years of experience in boosting IT-based startups to success. In the past, he has worked on leadership positions with Marriott Vacations, Disney, MasterCard, State Farm, and Oracle. The company headed by him excels in developing, implementing, and monitoring digital solutions ranging from IoT solutions and products, mobile and web development, and digital marketing to full stack development and CMS solutions.